Electric planes could be the future of aviation. In theory, they will be much quieter, cheaper, and cleaner than the planes we have today. Electric planes with a 1,000 km (620 mile) range on a single charge could be used for half of all commercial aircraft flights today, cutting global aviation’s carbon emissions by about 15%.

It’s the same story with electric cars. An electric car isn’t simply a cleaner version of its pollution-spewing cousin. It is, fundamentally, a better car: Its electric motor makes little noise and provides lightning-fast response to the driver’s decisions. Charging an electric car costs much less than paying for an equivalent amount of gasoline. Electric cars can be built with a fraction of moving parts, which makes them cheaper to maintain.

So why aren’t electric cars everywhere already? It’s because batteries are expensive, making the upfront cost of an electric car much higher than a similar gas-powered model. And unless you drive a lot, the savings on gasoline don’t always offset the higher upfront cost. In short, electric cars still aren’t economical.

Similarly, current batteries don’t pack in enough energy by weight or volume to power passenger aircrafts. We still need fundamental breakthroughs in battery technology before that becomes a reality.

Battery-powered portable devices have transformed our lives. But there’s a lot more that can batteries can disrupt, if only safer, more powerful, and energy-dense batteries could be made cheaply. No law of physics precludes their existence.

And yet, despite over two centuries of close study since the first battery was invented in 1799, scientists still don’t fully understand many of the fundamentals of what exactly happens inside these devices. What we do know is that there are, essentially, three problems to solve in order for batteries to truly transform our lives yet again: power, energy, and safety.

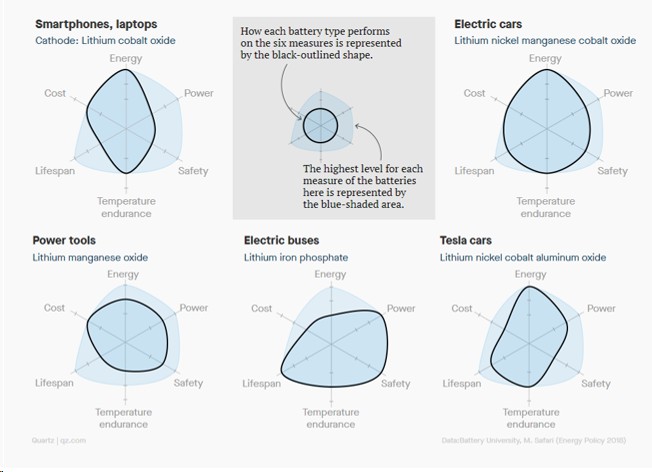

There isn’t a one-size-fits-all lithium-ion battery

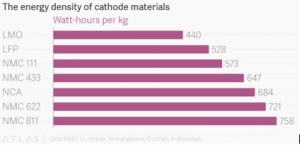

Every battery has two electrodes: a cathode and an anode. Most anodes of lithium-ion batteries are made of graphite, but cathodes are made of various materials, depending on what the battery will be used for. Below, you can see how different cathode materials change the way battery types perform on six measures.

The power challenges

In common parlance, people use “energy” and “power” interchangeably, but it’s important to differentiate between them when talking about batteries. Power is the rate at which energy can be released.

A battery strong enough to launch and keep aloft a commercial jet for 1,000 km requires a lot of energy to be released in very little time, especially during takeoff. So it’s not just about having lots of energy stored but also having the ability to extract that energy very quickly.

Tackling the power challenge requires us to look inside the black box of commercial batteries. It’s going to get a little nerdy, but bear with me. New battery technologies are often overhyped because most people don’t look closely enough at the details.

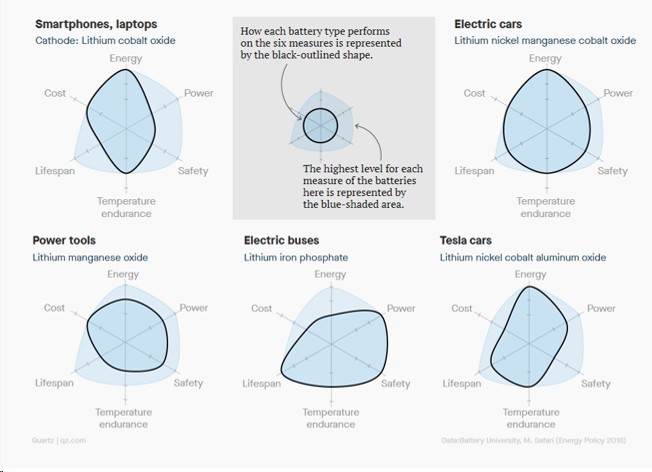

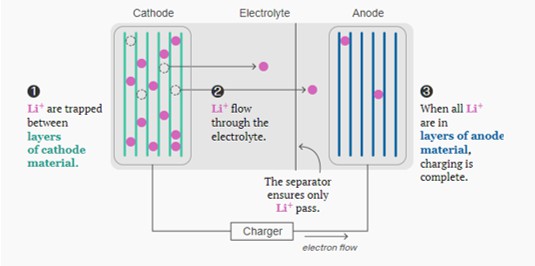

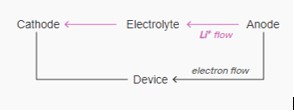

The most cutting-edge battery chemistry we currently have is lithium-ion. Most experts agree that no other chemistry is going disrupt lithium-ion for at least another decade or more. A lithium-ion battery has two electrodes (cathode and anode) with a separator (a material that conducts ions but not electrons, designed to prevent shorting) in the middle and an electrolyte (usually liquid) to enable the flow of lithium ions back and forth between the electrodes. When a battery is charging, the ions travel from the cathode to the anode; when the battery is powering something, the ions move in the opposite direction.

Inside a lithium-ion battery

While the battery is charging

Lithium-ions (Li+) flow from the cathode to the anode.

While the battery is in use

The same process happens, but in reverse. Li+ flow from the anode

to the cathode. When the anode is empty, the battery needs to be charged.

Imagine two loaves of sliced bread. Each loaf is an electrode: the left one is the cathode and the right is one the anode. Let’s assume the cathode is made up of slices of nickel, manganese, and cobalt (NMC)—one of the best in the class—and that the anode is made up of graphite, which is essentially layered sheets, or slices, of carbon atoms.

In the discharged state—i.e., after it has been drained of energy—the NMC loaf has lithium ions sandwiched between each slice. When the battery is charging, each lithium ion is extracted from between the slices and forced to travel through the liquid electrolyte. The separator acts as a checkpoint ensuring only lithium ions pass through to the graphite loaf. When fully charged, the battery’s cathode loaf will have no lithium ions left; they will all be neatly sandwiched between the slices of the graphite loaf. As the battery’s energy is consumed, the lithium ions travel back to the cathode, until there are none left in the anode. That’s when the battery needs to be charged again.

The battery’s power capacity is determined by, essentially, how fast this process happens. But it’s not so simple to turn up the speed. Drawing lithium-ions out of the cathode loaf too quickly can cause the slices to develop flaws and eventually break down. It’s one reason why the longer we use our smartphone, laptop, or electric car, the worse their battery life gets. Every charge and discharge causes the loaf to weaken that little bit.

Various companies are working on solutions to the problem. One idea is to replace layered electrodes with something structurally stronger. For example, the 100-year-old Swiss battery company Leclanché is working on a technology that uses lithium iron phosphate (LFP), which has an “olivine” structure, as the cathode, and lithium titanate oxide (LTO), which has a “spinel” structure, as the anode. These structures are better at handling the flow of lithium ions in and out of the material.

Leclanché currently uses its battery cells in autonomous warehouse forklifts, which can be charged to 100% in nine minutes. For comparison, the best Tesla supercharger can charge a Tesla car battery to about 50% in 10 minutes. Leclanché is also deploying its batteries in the UK for fast-charging electric cars. These batteries sit at the charging station slowly drawing small amounts of power over a long period from the grid until they are fully charged. Then, when a car docks, the docking-station batteries quick-charge the car’s battery. When the car leaves, the station battery starts recharging again.

Efforts like Leclanché’s show it’s possible to tinker with battery chemistries to increase their power. Still, nobody has yet built a battery powerful enough to rapidly deliver the energy needed for a commercial plane to defeat gravity. Startups are looking to build smaller planes (seating up to 12 people), which could fly on relatively lower power-dense batteries, or electric hybrid planes, where jet fuel does the hard lifting and batteries do the coasting.

But there’s really no company working in this space anywhere near commercialization. Further, the kind of technological leap required for an all-electric commercial plane will likely take decades, says Venkat Viswanathan, a battery expert at Carnegie Mellon University.

A two-seat electric plane made by Slovenian firm Pipistrel stands outside a hangar at Oslo Airport, Norway.

The energy challenges

The Tesla Model 3, the company’s most affordable model, starts at $35,000. It runs on a 50 kWh battery, which costs approximately $8,750, or 25% of the total car price.

That’s still amazingly affordable compared to not that long ago. According to Bloomberg New Energy Finance, the average global cost for lithium-ion batteries in 2018 was about $175 per kWh—down from nearly $1,200 per kWh in 2010.

The US Department of Energy calculates that once battery costs fall below $125 per kWh, owning and operating an electric car will be cheaper than a gas-powered car in most parts of the world. It doesn’t mean electric vehicles will win over gas-powered vehicles in all niches and domains—for example, long-haul trucks don’t yet have an electric solution. But it’s a tipping point where people will start to prefer electric cars simply because they will make more economical sense in most cases.

One way to get there is to increase the energy density of batteries—to cram more kWh into a battery pack without lowering its price. Battery chemist can do that, in theory, by increasing the energy density of either the cathode or the anode, or both.

The most energy-dense cathode on the way to commercial availability is NMC 811 (each digit in the number represents the ratio of nickel, manganese, and cobalt, respectively, in the mix). It’s not yet perfect. The biggest problem is that it can only withstand a relatively small number of charge-discharge life cycles before it stops working. But experts predict that industry R&D should solve the problems of the NMC 811 within the next five years. When that happens, batteries using NMC 811 will have higher energy density by 10% or more.

However, a 10% increase is not that much in the big picture.

And, while a series of innovations over the past few decades have pushed the energy density of cathodes ever higher, anodes are where the biggest energy-density opportunities lie.

Graphite has been and remains far and away the dominant anode material. It’s cheap, reliable, and relatively energy dense, especially compared to current cathode materials. But it’s fairly weak when stacked up against other potential anode materials, like silicon and lithium.

Silicon, for example, is theoretically much better at absorbing lithium ions as graphite. That’s why a number of battery companies are trying to pepper some silicon in with the graphite in their anode designs; Tesla CEO Elon Musk has said his company is already doing this in its lithium-ion batteries.

A bigger step would be to develop a commercially viable anode made completely from silicon. But the element has traits that make this difficult. When graphite absorbs lithium ions, its volume does not change much. A silicon anode, however, swells to four times its original volume in the same scenario.

Unfortunately, you can’t just make the casing bigger to accommodate that swelling, because the expansion breaks apart what’s called the “solid electrolyte interphase,” or SEI, of the silicon anode.

You can think of the SEI as a sort of protective layer that the anode creates for itself, similar to the way that iron forms rust, also known as iron oxide, to protect itself from the elements: When you leave a piece of newly forged iron outside, it slowly reacts with the oxygen in the air to rust. Underneath the layer of rust, the rest of the iron doesn’t suffer from the same fate and thus retains the structural integrity.

At the end of a battery’s first charge, the electrode forms it’s own “rust” layer—the SEI—separating the uneroded part of the electrode from the electrolyte. The SEI stops additional chemical reactions from consuming the electrode, ensuring that lithium ions can flow as smoothly as possible.

But with a silicon anode, the SEI breaks apart every time the battery is used to power something up, and reforms every time the battery is charged. And during each charge cycle, a little bit of silicon is consumed. Eventually, the silicon dissipates to the point where the battery no longer works.

Over the last decade, a few Silicon Valley startups have been working to solve this problem. For example, Sila Nano’s approach is to encase silicon atoms inside a nano-sized shell with lots of empty room inside. That way, the SEI is formed on the outside of the shell and the expansion of silicon atoms happens inside it without shattering the SEI after each charge-discharge cycle. The company, valued at $350 million, says its technology will power devices as soon as 2020.

Enovix, on the other hand, applies a special manufacturing technique to put a 100% silicon anode under enormous physical pressure, forcing it to absorb fewer lithium ion and thus restricting the expansion of the anode and preventing the SEI from breaking. The company has investments from Intel and Qualcomm, and it also expects to have its batteries in devices by 2020.

These compromises mean the silicon anode can’t reach its theoretical high energy density. However, both companies say their anodes perform better than a graphite anode. Third parties are currently testing both firms’ batteries.

In 2020, the new Tesla Roadster is set to become the first electric car that offers 1,000 km (620 miles) on a single charge.

The safety challenges

All the molecular tinkering done to pack more energy in batteries can come at the cost of safety. Ever since its invention, the lithium-ion battery has caused headaches because of how often it catches fire. In the 1990s, for example, Canada’s Moli Energy commercialized a lithium-metal battery for use in phones. But out in the real world, its batteries started catching fire, and Moli was forced to make a recall, and, eventually, file for bankruptcy. (Some of its assets were bought by a Taiwanese company and it still sells lithium-ion batteries the brand name E-One Moli Energy.) More recently, Samsung’s Galaxy Note 7 smartphones, which were made with modern lithium-ion batteries, started exploding in people’s pockets. The resulting 2016 product recall cost the South Korean giant $5.3 billion.

Today’s lithium-ion batteries still have inherent risks, because they almost always use flammable liquids as the electrolyte. It’s one of nature’s unfortunate (for us humans) quirks that liquids able to easily transport ions also tend to have a lower threshold to catching fire. One solution is to use solid electrolytes. But that means other compromises. A battery design can easily include a liquid electrolyte that’s in contact with every bit of the electrodes—making it able to efficiently transfer ions. It’s much harder with solids. Imagine dropping a pair of dice into a cup of water. Now imagine dropping those same dice into a cup of sand. Obviously, the water will touch far more surface area of the dice than the sand will.

So far, the commercial use of lithium-ion batteries with solid electrolytes has been limited to low-power applications, such as for internet-connected sensors. The efforts to scale up solid-state batteries—that is, containing no liquid electrolyte—can be broadly classified into two categories: solid polymers at high temperatures and ceramics at room temperature.

Solid polymers at high temperatures

Polymers are long chains of molecules linked up together. They’re extremely common in everyday applications—single-use plastic bags are made of polymers, for example. When some types of polymers are heated, they behave like liquids, but without the flammability of the liquid electrolytes used in most batteries. In other words, they have the high ion conductivity as a liquid electrolyte without the risks.

But they have limitations. They can only operate at temperatures above 105°C (220°F), which means they aren’t practical options for, say, smartphones. But they can be used for storing energy from the grid in home batteries, for example. At least two companies—US-based SEEO and France-based Bolloré—are developing solid-state batteries that use high-temperature polymers as the electrolyte.

Ceramics at room temperature

Over the last decade, two classes of ceramics—LLZO (lithium, lanthanum, and zirconium oxide) and LGPS (lithium, germanium, phosphorus sulfide)—have proven almost as good at conducting ions at room temperature as liquids.

Toyota, as well as the Silicon Valley startup QuantumScape (which raised $100 million in funding from Volkswagen last year), are both working on deploying ceramics in lithium-ion batteries. The inclusion of big players in the space is indicative that a breakthrough might be nearer than many think.

“We are quite close to seeing something real [using ceramics] in two or three years,” says Carnegie Mellon‘s Viswanathan.

A balancing act

Batteries are already big business, and the market for them keeps growing. All that money attracts a lot of entrepreneurs with even more ideas. But battery startups are difficult bets—they fizzle even more often than software companies, which are known for their high failure rate. That’s because innovation in material sciences is hard.

So far battery chemists have found that, when they try to improve one trait (say energy density), they have to compromise on some other trait (say safety). That kind of balancing act has meant the progress on each front has been slow and fraught with problems.

But with more eyes on the problem—MIT’s Yet-Ming Chiang reckons there are three times as many battery scientists in the US today than just 10 years ago—the chances of success go up. The potential of batteries remains huge, but given the challenges ahead, it’s better to look at every claim about new batteries with a good dose of skepticism.

This story was published April 8, 2019.

Credit : www.qz.com